HVAC Controls to save the Poles!

Wednesday, February 11th, 2009In almost all commercial buildings, the Heating Ventilation & Air Conditioning (HVAC) system uses the largest percentage of power. Like lighting, the HVAC operates throughout business hours but its plant consumes much larger amounts of energy. Traditionally HVAC systems source heating from gas (oil in some cases) fired boilers, and cooling from electric chilled water or refrigerant plants. Reverse cycle package air conditioners produce heating and cooling via compressors within the unit. Most large HVAC systems are centrally controlled via a Building Management System (BMS), which activates the heating or cooling relative to the demand within the serviced area. This is controlled via a temperature set point, proportional bands and dead bands.

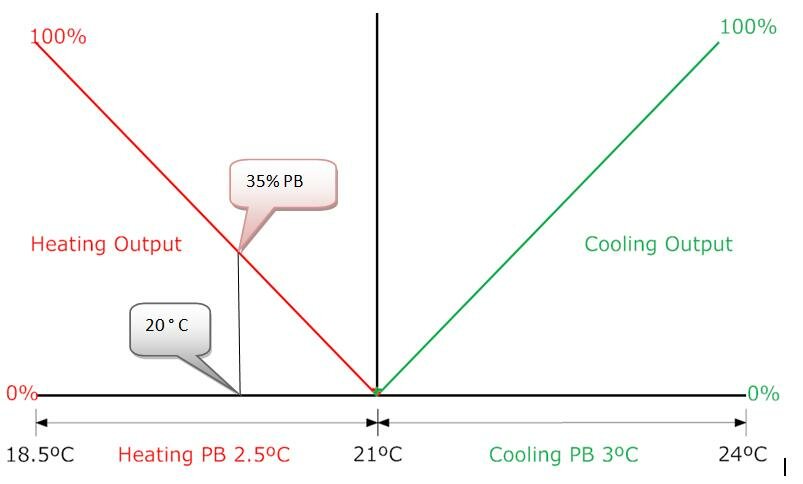

Shown below is a simple temperature control proportional–integral–derivative (PID) controller diagram. It shows a temperature set point and heating cooling proportional bands (PB) or percentage heating/cooling.

When the thermostat within the room reads a temperature below 21 degrees the percentage heating (PB) will begin to rise. When the proportional band reaches 35% the boiler is activated and will continue to heat until 0% PB (set point) is reached. This is unnecessary because as you can see, the temperature has only dropped 1°C from 21°C to 20°C, which is still comfortable for occupants. Also, heating should not continue until 0% PB as this will cause the room to overheat and subsequently call for cooling.

This type of control configuration creates a plant room scenario similar to that in the engine room of the Titanic! The boiler and chiller are constantly in operation in order to maintain the tightly controlled set point. Comfort levels within the serviced area are also compromised as occupants constantly feel surges of warm air followed by surges of cool air.

This problem can be easily averted by changing the control settings. Within the BMS, the boiler and chiller settings can be manipulated. If the heating percentage PB is brought out to 65% for instance, the boiler will not be activated until the room temperature reaches 19.3°C, which is still not cold for occupants. Also the boiler should be programmed to cut out at 25% PB as there will be a delay on the heated air getting to the thermostat. The room will still reach set point even though heating stops at 20.3°C. This will avoid the set point being unnecessarily exceeded and the cooling being activated. The same control fundamentals apply for packaged air conditioners.

The potential savings from the alteration of simple control bands are huge. The run times of both the boiler and chiller are significantly reduced, which shows up on your energy bills. At first occupants may complain that it is too hot or too cold. If this arises, have a thermostat close at hand to check that temperatures are within standard office comfort conditions (see “What is a comfortable office temperature” Bruce Rowse Dec ’09). Advise them on appropriate dress if they are experiencing discomfort. It may also help if they are advised as to why these modifications have been made and what has been achieved.

I have been involved in a lot of these control system alterations and I can safely say that it is the cheapest, easiest and fastest way to achieve significant electricity, gas, money and greenhouse gas savings from the your largest energy consumer, the HVAC system.