Sunlight in a Cable

Wednesday, February 25th, 2009We are all familiar with the concept of the traditional skylight or solar tube that directs sunshine through a duct or a flexible tube from the roof to a ceiling. This is an easy way to get natural daylight into a room but it is dependent on tube length and on a direct route between the roof top and the ceiling. There is another way known as ‘fiber optic solar lighting technology’.

Parans , the Swedish company behind the ‘sunlight in a cable’ concept, believes that it is possible to have sunlight in every single room of an indoor environment - even underground. The principle of the Parans’ system is simple; first the sunlight is collected by panels outdoors then it is transported through fiber optic cables into carefully designed luminaires located anywhere within a building including between floors.

The system consists of a light-collecting panel called a SkyPort that’s made up of a layer of movable and a fixed layer of lenses that track the movement of the sun through stepping motors controlled via a microcomputer. These can be mounted on a roof, facade or the ground just like other solar collecting devices; however glare shields may be used to throw direct sunlight onto its surface if the orientation is not quite perfect. The SunWire, consisting of a bunch of optical cables, then guides the sunlight indoors with minimum light loss. Very high quality light can be transported for up to 15-20 metres without major losses since the decrease of intensity for visible light is only 4.6% per metre.

The Björk luminaires are designed to give a spectacular sunlight experience both as strong light beams and as ambient light. The luminaires are made from thin sheets of semi-transparent acrylic. The feeling of natural light is immediate. The light intensity under one of these luminaires can be as high as 4000 lux when 100 000 lux outdoors (based on seven metres of fiber optic cable). UV and IR radiation are naturally blocked out by the Parans system making it the perfect solution for environments where these must be avoided. It is possible to ‘switch off‘ the system in case the darkening of a room is necessary for presentations etc.

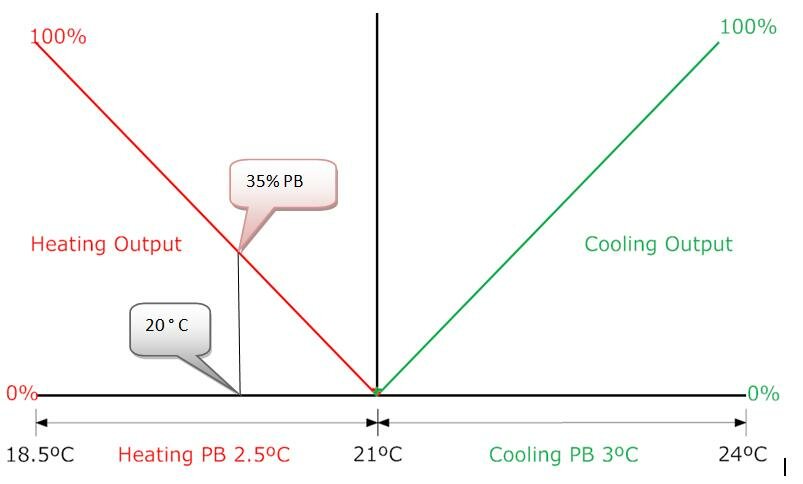

While the Parans system works perfectly well in reasonable daylight conditions it is necessary to use artificial lighting during overcast days or when the hours of daylight diminish in winter. To counteract this there is a hybrid luminaire that incorporates T5 lighting technology, which dims automatically according to how much natural light is emitted.

However, the main focus of the system is to harness as much sunlight as possible before needing any artificial lighting thus reducing energy costs and most importantly greenhouse emissions. The only power the Parans system uses is 0.9W for the motorised panels and the microprocessor. Using the Parans lighting system can lower energy costs by 20-25% annually and probably around the same percentage of GHG emissions (based on brown coal emissions).

(Ref: www.parans.com and www.skydome.com.au)