What will make zero net energy office buildings affordable by 2020?

Wednesday, September 16th, 2009A zero net energy office building is one which consumes no net energy. Its an office that uses very little energy, then has some form of renewable energy to generate all the power it requires.

With current off the shelf solar technology, presuming little or no shading, its possible to get around 100 kWh of energy per year per square meter of solar panels at latitudes of around 40 degrees, more in sunny locations at lesser lattitude. For a single storey building, with a roof covered with solar panels, and little shading, keeping office energy consumption to 100 kWh/m2 is easy, and in fact I’ve audited quite a few small offices that are nothing special but only use in the order of 100 to 120 kWh/m2. But a grid connect solar system nowdays costs in the vicinity of $700 to $1,000 per square meter, which is pretty expensive, so there are very few zero net energy offices in existence.

Aggressive energy conservation and use of off the shelf technology (like skylights) can mean that office energy consumption is kept down to somewhere between 30 to 50 kWh/m2, meaning only half the roof needs to covered with solar panels, or allowing for some shading. For example our office uses only 30 kWh/m2/year, but is shaded in winter, we could make it energy neutral now just by covering around 2/3rds of the roof in solar panels.

So it is possible now, in 2009, to have a zero net energy office, but its not easily affordable, yet. And if your office is 3 storeys or higher, its becomes very hard to achieve no matter what your budget.

Technological advances however, are happening rapidly and I believe that by 2020 a zero net energy low-rise office may be affordable. And importantly this should be achievable by retrofitting an existing office building, with no need to especially construct a new building. Some of these technological changes are:

- The emergence of LED lighting. Assuming by 2020 we have LED lighting of around 200 lumens per watt. Allowing for some daylighting, and good use of task lighting, it may be possible to have annual lighting use less than 8 kWh/m2/year.

- Computer efficiency improvements. Assuming that with thin client architecture and high efficiency monitors by 2020 an office PC uses 15 watts, and that a 200 watt server can then serve 30 clients, computer energy use would be around 3 to 4 kWh/m2/year.

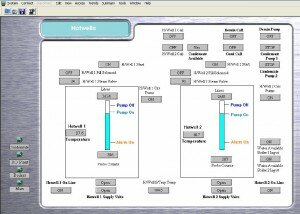

- There are many likely pathways for HVAC, which will depend on climate. A likely pathway for temperate climates is 100% fresh air HVAC systems, with air to air heat exchangers, but also using legacy internal ducting to allow high flow full economy cycles. Fans will be highly efficient, and heat pumps will have high efficiencies at a range of loading conditions, with the conditioning of air separated from ventilation to lower fan energy use. Couple this with light weight retrofit phase change materials (PCM) to provide thermal mass (eg plasterboard with encapsulated PCM), white roofs (where there are no solar panels), glazing treatments and new insulating membrane technologies to improve the thermal performance of the building. Seal the building well, and combine with good use of sensors and intelligent control all of which limits HVAC energy use to say 15 kWh/m2/year.

- Miscellaneous loads: high efficiency fridge at say 150 kWh/year; near zero standby loss hot water system; high efficiency multi function devices, totalling say 4 kWh/m2/year.

This will result in total office energy use of around 30 kWh/m2/year.

With aggressive energy conservation occupants should be able to to get down to say 15 to 20 kWh/m2/year.

Assume solar panel efficiency is more than double current efficiency and the installed price per watt of a grid connect system is one third of the current cost. This will provide 260 kWh/m2/year at a cost of say $500 per square meter.

A single story unshaded office where aggressive energy conservation is practiced will then need only 8% of its roof covered with solar panels, at a cost per square meter of building area of only $40.

A three storey half shaded office building would need most of its roof covered.

It should be possible to have a 7 storey building energy neutral if unshaded and the roof is covered with solar panels. Of course if additional solar panels can be added to walls it should be possible to get even taller energy neutral buildings.

By 2020 the net zero energy low-rise office building should be easily affordable, and in fact it may well be standard good financial practice to convert existing office buildings to energy neutral ones. So even building owners with no interest in acting to slow climate change will have energy neutral buildings. And most low rise office buildings then - whether they are 100, 50, or 1 year old - could be energy neutral.

I say “should” and “may” because I still have some doubt as to whether a couple of the technologies that modify the thermal performance of a building – particularly PCMs, and retrofit membrane’s that improve its insulation properties – will be affordable. But then again with focus a lot can change in 11 years, and as more of us demand better energy performance from our buildings I believe that this will spark the innovation needed to make zero net energy office buildings common place.

You can help make this a reality by acting now to make your building more efficient. Do what is affordable now. Then repeat regularly - technology is now advancing quickly. You’ll create the demand that will drive the innovation that will create the technology that will make energy neutral buildings common place.