Energy saving opportunities in dynamic office spaces

Monday, May 18th, 2009During energy audits, our team often finds situations where walls or partitions have been moved or an extension has been added to a building and the electrical and mechanical services have not been considered. This leads to reduced occupancy comfort and energy wastage. The major energy saving opportunities lie in the duct design and the lighting layout. The following case study examines the opportunities brought about by re-examining duct design.

(part 1) HVAC opportunities

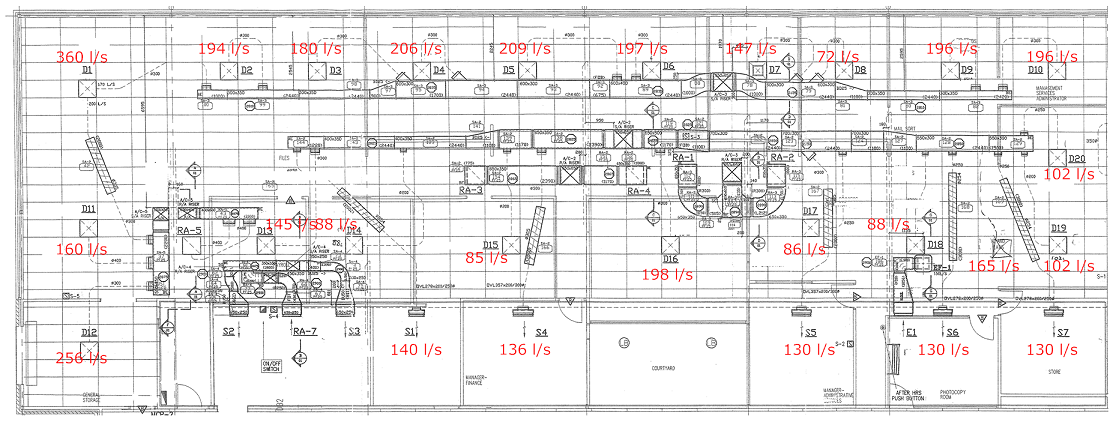

The following diagrams show a case study of an existing duct layout where an extension has been added on the west facing windows of the office. Measuring the flow rates of the packaged units servicing the area alerted us to the fact that air velocities were excessive and fresh air rates were greater than 10 litres per second per person.

Figure 1 – Mechanical service duct layout with measured diffuser air velocities

What is the affect of high air velocities and what energy saving options does this present?

High air velocities cause wind chill. Wind chill is a convection process which increases the transfer of heat from surfaces such as skin and clothes.

Figure 2 – Wind chill cartoon from

www.r-p-r.co.uk/wind_chill_table.htm

In figure 1, occupants were complaining of feeling cold even though the temperature in the area was measured at a comfortable 23 degrees Celsius.

Rule of thumb

At 25 degrees C, an air speed of 1m/sec will be felt by the body as 2 degrees cooler.

If air velocities are too high there may exist an opportunity to slow the air handling fan down. This can be done via the installation of a Variable speed drive (VSD) or in belt driven fans, by changing the pulley size. Both of these methods result in fan energy savings.

Note: care must be taken not to reduce the air speed excessively in refrigerant systems as this could lead to malfunction or excessive wear and tear on the unit.

It is also important to consider what happens to the fresh air volume when slowing down air handling systems. If the fresh air intake is set to 10% which provided the occupants with precisely 10 litres per second per occupant and then adjustments are made to reduce the air flow rate by 25%, this would result in new fresh air volumes of 7.5 litres which may be too low. In a fixed fresh air system this may mean opening the fresh air damper (if it is adjustable) and in a modulating system, this will require adjustments at the controller or in the Building Management System (BMS).

An alternative to increasing the fresh air rate may exist in installing CO2 monitoring. The opportunities of which will be the subject of a later blog.

In our case study we have identified that there is an abundance of air volume and higher than required fresh air volumes. The small west positioned packaged unit was installed initially to service a different heat load presented by the west facing glass. Since then the building has been extended and the glass is now internal. This has the effect of reducing the heat load on this part of the office.

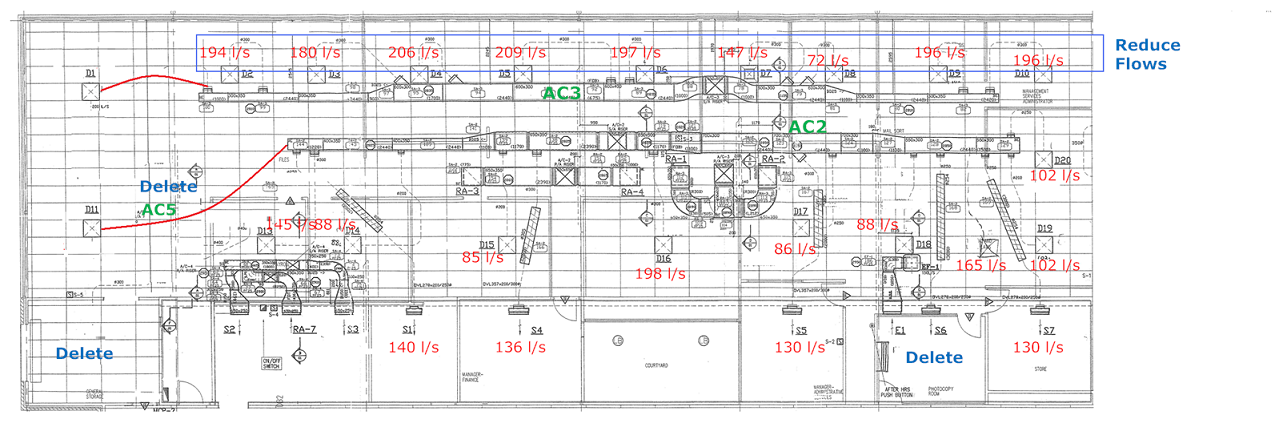

By simply reviewing duct design, a complete packaged unit has been removed from service!

By measuring the air volumes at each diffuser we can determine the quantity of excess air and how we can balance the system to improve occupancy comfort. Auditing the diffusers also highlighted some areas that did not require air conditioning such a store room, and a copy room that has been retrofitted with its own split system and extraction system (see diagram above). The following diagram shows the new layout of the HVAC ducts. Note that AC unit 3, and 4, have been extended to allow the removal of AC unit 5. By simply reviewing duct design, a complete packaged unit has been removed from service.

Figure 3 – Mechanical services duct layout after changes

It should be noted that this analysis has been made significantly easier because of the access to up to date mechanical services drawings and accurate floor plans. As any alterations are made to buildings it is important to update the floor layouts, mechanical, and electrical services drawings. If your facility does not have up to date drawings, it may be worth while seeking the services of a drafting company to develop a Computer Aid Design (CAD) set. This will allow the facilities department to track any changes as they occur and allow more efficient analysis of problems for contractors which ultimately will result in faster and more comprehensive analysis of problems.