If LED lighting continues to develop as fast as it has over the last five years, within ten years it may well be the main form of lighting in use across the world. And lighting in new buildings may look radically different to what it does now.

The major advantage of LEDs is that they are a directional light source. Most other artificial light sources on the market radiate light in all directions. Incandescent light bulbs, compact fluorescent lamps, fluorescent lamps and high intensity discharge lamps such as metal halide all radiate light in all directions.

For example in most fluorescent office light fittings typically only 60% of the light produced by the fluorescent tube is emitted as useful light. A great deal of the light is lost because it goes upwards or sideways rather than down. Using a reflector may increase the amount of useful light provided up to 80%. But even the most efficient fluorescent light fittings on the market rarely have a light output ratio of above 80%.

LED lights on the other hand produce all their light in a single direction. Light fitting designers can take advantage of this to efficiently direct light exactly where its needed, with very little lost or wasted light.

Go into a progressive hardware or electrical store and you can already see a variety of LED lights being sold.

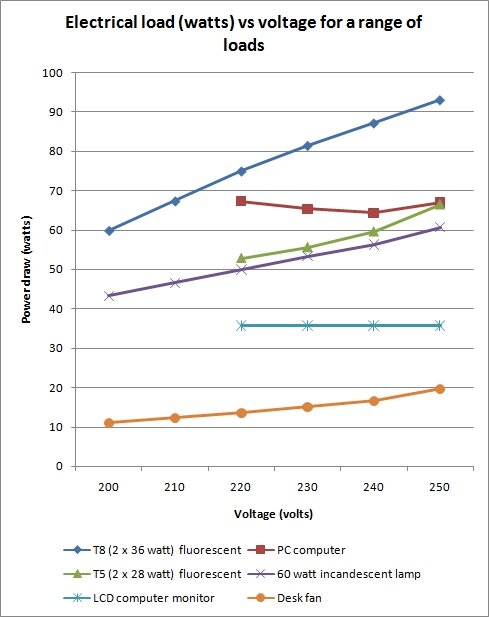

Fluorescent lamps are the most commonly used lamp in the world. LEDs however are not yet competitive with fluorescents for three main reasons:

- Energy efficiency is similar but not yet better. A high performance fluorescent tube will produce 100 lumens per watt. Put it in an energy efficient fitting, with a light output ratio of 80%, and the overall lighting efficiency is 80 useful lumens per watt of electricity. The best white LEDs on the market (that we are aware of) produce 75 to 80 lumens per watt. This is good, but not yet better than, fluorescent.

- Reliability. Unlike fluorescent tubes, which are generally reliable no matter who makes them, LEDs are often unrealiable. We have purchased LEDs from many different manufacturers, and over half have failed within the first year of use.

- Price. LEDs are still expensive.

This, however, is changing. Energy efficiency is improving, the major lighting manufacturers are increasing their focus on LEDs, and prices are dropping.

Energy efficiency of LEDs has increased markedly in recent years, in 2006 the best LEDs were approaching 60 lumens per watt, by the end of 2008 they were up to 77 lumens per watt.

Reliability. The three main global light manufacturers – Osram, Philips and Sylvania – are all now selling LED lights. As major global brands they are unlikely to risk the cost and reputational damage of supplying unreliable products. As LED products become more main stream we can expect reliability to improve.

Costs are now starting to decrease as well. Whilst it is difficult to purchase a LED fluorescent substitute light for less than $80, only two years ago the price was $100.

When LED lights are achieving energy efficiencies in excess of 120 lumens per watt, lamp costs of less than $2 a watt, and low failure rates (less than say 1%) lighting as we now know it will be superseded. It will be possible to retrofit LEDs and cut lighting energy use by 50% or more in almost any building. New buildings, with lighting designs built around LEDs, may well be providing office – standard illumination for 2 watts of electricity use per square meter or less (current best practice is around 5 watts per square meter).

These new lights may look very different. Light fittings may become panels with hundreds of LEDs on them. Or ceilings may end up with stripes of LEDs across the ceiling. Or ceilings will end up with sockets into which panels of LEDs can be plugged in, so that its easy to move LEDs around in response to the lighting needs of a room (more above a desk, less in the corridors).

If control and sensing technologies can become sufficiently low cost buildings may well be set up to provide lighting whose intensity varies with occupancy and usage.

The rapid development of LEDs is exciting. It gives me hope that, when it comes to lighting, humanity will be able to greatly reduce its carbon footprint in the not too distant future.